Introducing the SCM Lean Booster: Transforming Refrigeration Solutions

Introducing the SCM Lean Booster: Transforming Refrigeration Solutions

The trend of reducing supermarket sales areas due to the rise of online shopping and the proximity concept of stores has been ongoing for several years. While pinpointing an exact starting point is challenging, this trend has been noticeable for at least the past decade.

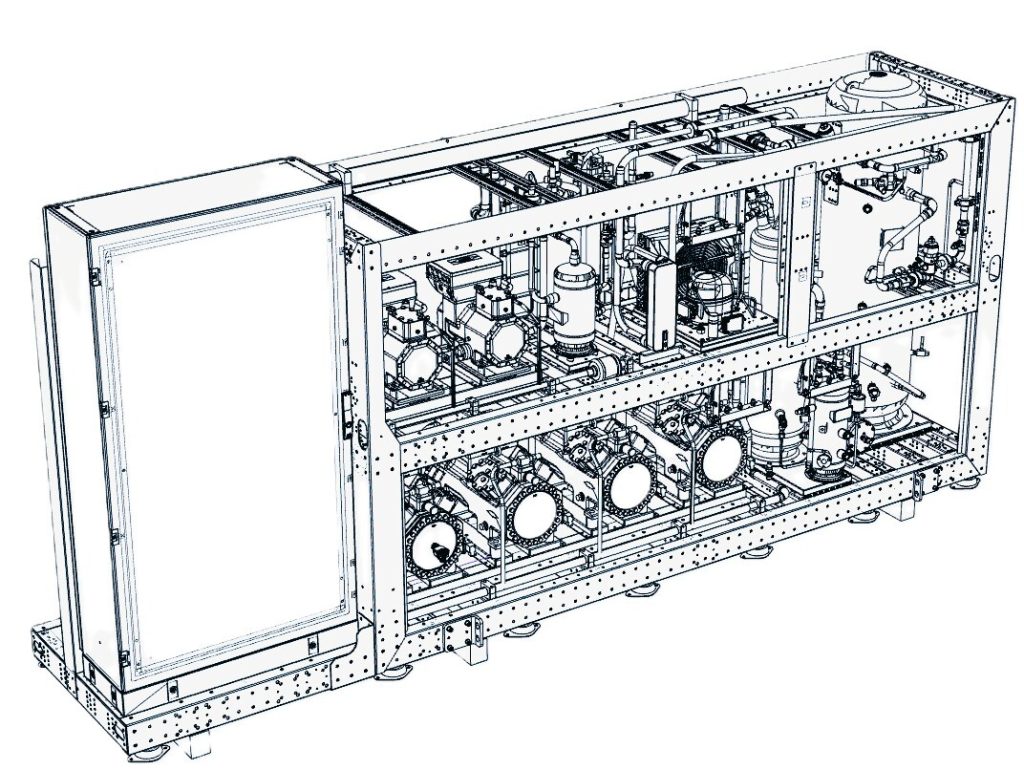

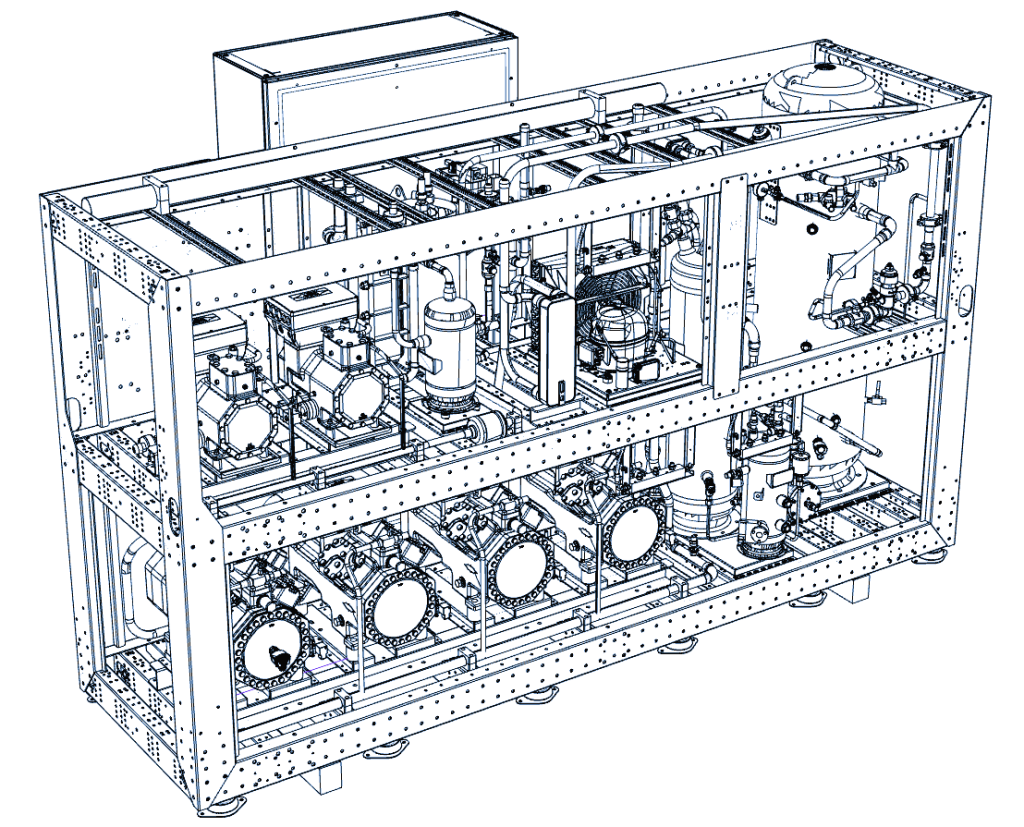

In response, SCM Frigo developed a product tailored to this new trend: a smaller rack that is almost ”ready-to-go”, reducing lead times while providing a reliable and future-proof solution. The SCM Lean Booster is a state-of-the-art refrigeration solution crafted for diverse applications such as convenience stores, supermarkets, and even industrial settings. This innovative product line offers exceptional flexibility, efficiency, and customization to meet the varied needs of modern businesses, ensuring short delivery times through unit standardization and optimized production processes.

Key Features and Applications

Capacity Range:

- Medium Temperature (MT): 15-130 kW

- Low Temperature (LT): 3-28 kW

- Suction group possibilities: MT only / LT only / MT + LT / MT + IT + LT

Highlights:

- Compact design with easy access to components from one side, allowing installation against a wall.

- Available in indoor or “plug’n cool” versions for versatile installation options.

Innovative Options and Configurations

The Lean Booster offers a variety of advanced options to enhance its functionality and efficiency, including:

- Parallel Compressor Configuration: Allows for improved redundancy and efficiency.

- Digital Capacity Modulation: Ensures precise control over cooling capacity.

- Warm Climate Add-ons: Possibility of integration of mechanical subcooler, parallel compressor, water-spray and adiabatic systems and low pressure ejetor

- Heat Recovery: Options for both tap water and heating applications, providing energy savings and sustainability.

- A/C load with flooded evaporator: Option for comfort cooling applications

- Outdoor Units: Options for outdoor enclosed units with or without integrated gas coolers

Overcoming the challenges

To keep transcritical CO2 systems running smoothly in warm climates, smart tactics and improvements are essential. Here’s a breakdown of what can be done:

Better system design

The goal is to improve heat transfer efficiency and overall performance. This could mean bigger heat exchangers, better pipe layouts to reduce pressure loss, and integrating secondary loops or subcooling circuits to keep system stability.

Smarter Controls

To keep these systems efficient in the heat, we can use advanced software that predicts the weather and adjusts the system before it gets too warm. Adding sensors and real-time monitoring helps provide real-time feedback and optimization

Better Heat Rejection

Improving how the system rejects excess heat is key, especially with the design and operation of condensers. Making sure this component of the system can deal with high temperatures means the whole system uses less energy and stays more reliable.

Continuous monitoring and maintenance

Regular monitoring and maintenance are crucial. This means watching the system’s vital signs like pressure and temperature and doing routine tasks like cleaning components and fixing leaks to keep the system running smoothly.

Real example of customization of a standard product

In a period of three months, in response to a fast need for adaptation, SCM Frigo designed a solution for one of the world’s top-rated food retailers.

In the MWL standard solution, the electrical panel is integrated into the compressor rack with front access only, without doors on the rear side.

Due to the often restrictive size of machinery rooms, which are becoming smaller with the new trend of supermarkets or due to the retrofit of old stores, it is sometimes necessary to separate the electrical panel from the compressor chassis and mount it on a wall. To accommodate this, the panel is delivered with an extended electrical cable, already wired and the eletrical panel can be placed against a wall.

If space constraints are even tighter and the electrical panel cannot be positioned against a wall, the alternative solution is to attach the electrical panel to the back of the compressors without compromising maintenance accessibility.

Future

The SCM Lean Booster is a versatile and innovative refrigeration solution that delivers unparalleled flexibility and efficiency. Whether for small convenience stores, large supermarkets, or industrial applications, the Lean Booster offers tailored solutions to meet specific customer needs.

Building Connections

On LinkedIn

Become a CO² Specialist

Beijer Ref Academy will offer technicians and installers the opportunity to learn how to operate CO2 refrigeration systems in different configurations.