MAINTENANCE FAQ

How does the Pump Down procedure inside the Liquid Receiver take place?

Pump down procedure:

Pump down to the receiver will be carried out in case of service to the system on both HT and LT side or when the system is going to be turned off for prolonged periods.

It is recommended to lower suction set points on the pack controllers to limit the amount of refrigerant which will be vented when components are accessed.

When forcing compressors to run below operating set point, never go below 6 bar in the low pressure side to avoid reaching the triple point.

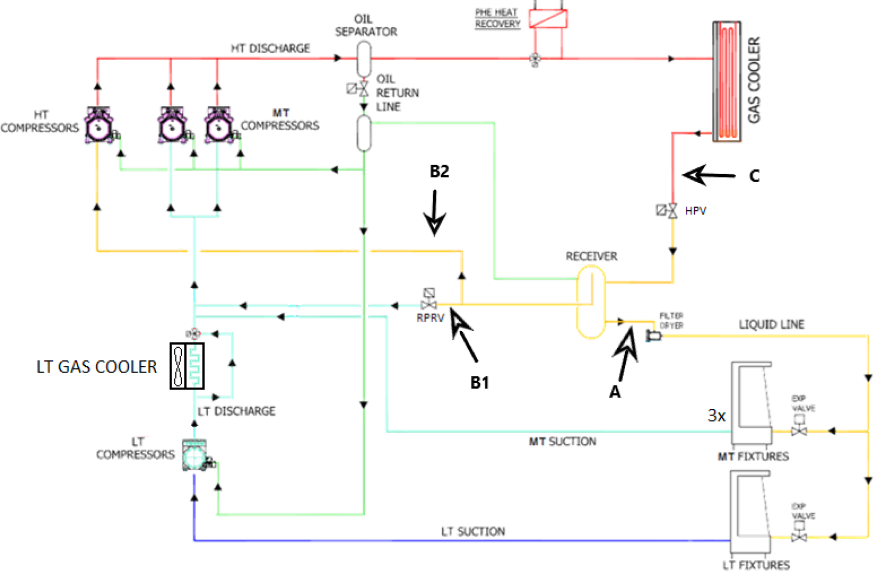

- Cut-off liquid delivery to cabinets to empty the liquid line by closing the ball valve close to the liquid filter.

(see position A in diagram a below). - Let the user’s evaporators keep regulating the temperature.

Let the system repeat a few cycles of starting and stopping in order to recover most of the refrigerant in the receiver.

Allow and wait MT and LT compressors to stop at pump down settings when reaching pressure set point. - Force the opening of the evaporators electronic expansion valves.

Let the system repeat a few cycles of starting and stopping in order to recover most of the refrigerant in the receiver. - Cutting off any ball valve between the Liquid receiver and MT/ Parallel Suction (see position B1 and B2).

- Cutting off the ball valves in series to the Ejector inlets/outlet (if installed).

- Start the resilience unit.

Switch ‘SAEBK’ to ‘on’ to manually run the resilience unit (see picture b below). - Switch off compressors.

On the front panel put the compressor switches to “0” (see picture c below). - Close the High pressure side by closing the ball valve in front of the HPV valve (see position C).

- Switch off the main power to the unit and check that the RU unit is still in operation.

Most of the system charge is now restricted in the receiver and the system is now ready for service; remember to empty the area to be serviced using the service valves.

Picture A:

| Picture B: | Picture C: |

|  |

Start after pump down:

- Switch on the main power to the unit and check the oil heaters are activated.

Do not turn on the compressors immediately.

Wait for the oil temperature to be about 20K higher than the ambient temperature. - Switch on compressors.

On the front panel put the compressor switches to “auto”. - Open high pressure side.

- Open the ball valve between the Liquid receiver and MT/ Parallel Suction.

The suction pressure could start rising and the compressors will cut in gradually. - Disable all the evaporators to force the closing of Electronic expansion valves.

- Slowly Open liquid line valve.

- Progressively put in operation the MT users and then the LT users (Expansion valves on the cabinet back in operation).

- Put the resilience unit in ‘auto’ mode (Switch SAEBK to off).