REFRIGERANT FAQ

How does the refrigerant charging procedure take place?

Charging Procedure:

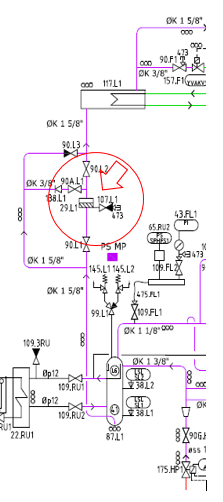

- The refrigerant charge must be done from the Liquid/ Receiver side. See the picture on the right side.

- Be sure all the valves in the units and in the installations are open.

- Fill the system with vapour CO2 up to reach 10bar (to be sure to be above the triple point). Take care that all parts in the circuits are at 10 bar.

- Shut off all expansion valves in the evaporators

- Shut off liquid line ball valves

- Check all valves for correct positioning

- Open all service valves on compressors

- Enable the main pack controllers regulation (Main Switch ‘ON’. LT compressors must be disabled)

- After that, fill the liquid receiver with liquid CO2

- Check that the Flash valve opens

- Check that a MT-compressor starts (Start up the unit with only one compressor per time)

- When the CO2 charge is almost completed (the lower sight glass level in the receiver has been reached) open the liquid line carefully.

- We suggest to keep all the evaporator controllers off and then open carefully the liquid line. Then it is recommended to verify that all expansion valves are really closed by monitoring the suction pressure (also on LT side).

- Enable the regulation of half of the MT electronic evaporators (the other half are kept closed)

- Allow the MT operating conditions to stabilize with the current MT electronic expansion valve open (50% MT operating capacity). Monitor especially the superheat on the compressor pack and on each evaporator.

- Complete the MT start-up procedure by opening and adding the remaining MT evaporators for stabilized operating conditions at full capacity (100% MT operating capacity).

- Check that the receiver pressure and condenser/gas cooler pressure regulates correctly and add up refrigerant if needed.

- Start-up of LT side as second step.

- Enable the regulation of half of the LT electronic evaporators (the other half are kept closed).

- Check that a LT-compressor starts.

- Allow the LT operating conditions to stabilize with the current LT electronic expansion valves open (50% LT operating capacity). Complete the LT start-up procedure by enabling and adding the second half of LT evaporators for stabilized operating conditions at full capacity (100% LT operating capacity).

- At the end of the charge the CO2 in the receiver should stay between the bottom Sight Glass and the one in the middle.